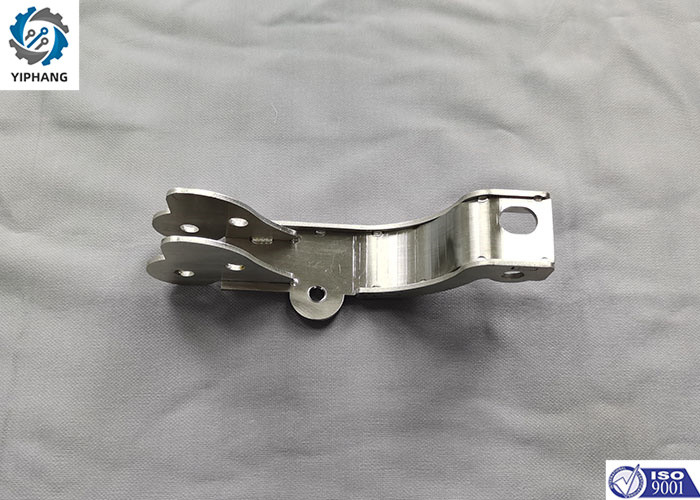

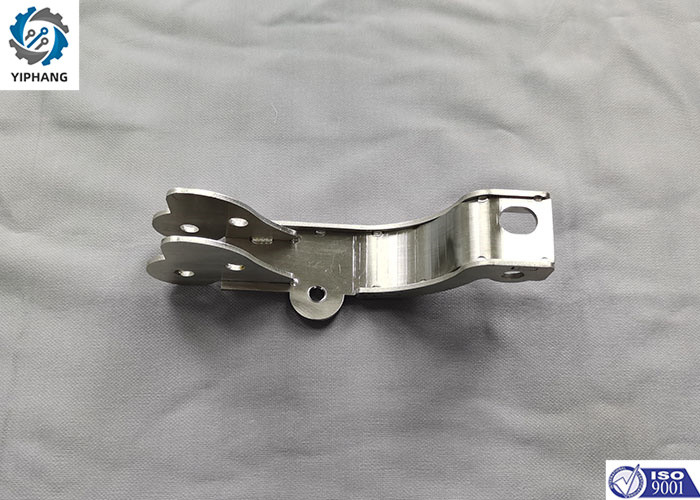

Custom Precision Sheet Metal Stamping Bending Strainless Steel

Fabrication Steel Bracket Fabrication

Sheet Metal Fabrication Services

ISO 9001:2008 certified Yiphang utilizes ongoing employee training,

automation, continuous process improvement and innovation to

maximize the quality, reliability, and cost-effectiveness of your

components.

Parts are carefully examined throughout the production process at

multiple quality control checkpoints and all shipments are

thoroughly tested and inspected before they are released to your

facility. As a result, our team has been able to consistently

maintain a nearly 0% external part reject rate that has enabled

many of our customers to eliminate the costly and time eroding

process of inbound part inspection.

We have a full-time AWS certified inspector and each of our welders

is qualified to one or more of the following specifications and/or

codes:

AWS D1.1-Structural Welding Code-Steel

AWS D1.2-Structural Welding Code-Aluminum

AWS D1.3-Structural Welding Code-Sheet Steel

AWS D1.6-Structural Welding Code-Stainless Steel

AWS D14.3-Specification for Welding Earthmoving Construction and

Agricultural Equipment

AWS D15.1-Railroad Welding Specification for Cars and Locomotives

EN 287-1-Qualification Test of Welders-Fusion welding-Part 1:

Steels

DIN EN 15085-Railway Applications. Welding of Railway Vehicles and

Components.

Customer specific welder qualifications.

Material Info & Types

- A36 is a very common mild steel. It is much easier to form than CRS

1018, but more difficult to machine.

- A653 Galvanized is a steel that contains zinc coating for protection against

corrosion.

- Stainless Steel (CRES) is an alloy based on chromium and steel and is categorized by its

resistance to corrosion. The gauge thickness is the same as regular

steel. Stainless is much harder than regular steel and is not easy

to work with in some respects. Our lasers love it and have no

problem cutting it. However, it is difficult to punch, and can be

difficult to weld. Below gives a description of the different

stainless types:

- CRES 304 is the most widely used multipurpose stainless steel which is easy

to weld and form.

- CRES 301 is commonly used for fasteners and springs which offers better

wear resistance and fatigue than 304. This type has good

weldability.

- CRES 316 has great corrosion resistance compared to 304, so it is best used

for chemical processing applications. This type has good

weldability and temperature resistance.

- CRES 303 is a good material to machine, which makes it best used to create

screw machine products. It is also good for corrosion resistance

and temperature.

- CRES 410 is commonly used for fasteners, machine parts, and shafts since it

can be heat treated for extra hardness and extra wear resistance.

- Aluminum are mixtures of aluminum with other metals, often with copper,

zinc, manganese, silicon, or magnesium. There are too many alloys

of aluminum to list. The number after the 4 digit code is the

tensile strength or temper of the alloy that ranges from T0 to T6.

T0 is soft, and T6 is full hard. VIP uses, 5052-H32, 6061-T6,

6061-T4, 2024-T0 for most of our parts. Below gives a description

of the different series of aluminum:

- 5052-H32 is the most common alloy we use. It has excellent corrosion

resistance, easy to form, and easier to weld. It is not heat

treatable and nonmagnetic.

- 6061-T6 is a multipurpose aluminum with good strength, corrosion

resistance, and machinability. It is heat treatable but

nonmagnetic.

- 2024 has great strength compared to mild steel, but weighs a lot less

and has less corrosion resistance than 7075. It is heat treatable

but nonmagnetic.

- 7075 is a very strong and lightweight aluminum with better corrosion

resistance than 2024. It is commonly used for aircraft parts which

is where it gets its common name "aircraft aluminum."

Sheet Metal Thicknesses

| Steel / Stainless Steel | Aluminum |

| Gauge | Thickness | Gauge* | Thickness |

28

26

24

22

20

18

16

14

12

11

10

8

7 | 0.015”

0.018”

0.024”

0.030”

0.036”

0.048”

0.060”

0.075”

0.105

0.120”

0.134”

0.160”

0.1874” | 22

20

18

16

14

12

11

10 | 0.025”

0.032”

0.040”

0.050”

0.063”

0.080”

0.090”

0.100”

0.125”

0.160”

0.190” |

| 3/16” and thicker is plate | THERE IS NO OFFICIAL GAUGE STANDARD FOR ALUMINUM 0.250” and thicker is plate *American Wire Gauge |

Metal Fabrication Capabilities

Here at Yiphang, we have a wide range of capabilities to meet our

customers’ metal fabrication needs. We specialize in precision sheet metal, CNC machining, and welding fabrication.

Similar Products

Are you a factory or trader for sheet metal fabrication and laser

cutting services?

We are an ISO 9001 certified factory specialized in sheet metal

fabrication and laser cutting services.

Does Yiphang Hardware have any certifications?

We have ISO 9001: 2015.

What services does Yiphang Hardware offer?

Our services include laser cutting, punching, shearing, bending,

welding, profiling, stamping, insertion, finishing, and assembly.

What kind of welding services do you offer?

Yiphang Hardware offers certified welding services including MIG

and TIG welding, as well as Spot welding and Stud welding services.

Yiphang Hardware has experience in welding a variety of metals such

as Alloy, Stainless Steel, Aluminum, Chromium Molybdenum Steel

(Chrome Molly), Cold Rolled Steel, High Carbon Steel, Hot Rolled

Steel, Copper, Titanium, and Brass.